From preserving food to containing beverages, cans are everywhere in our daily lives. Every can that pass through a production line carries information conveying its history and contents.

What are the benefits of Marking and coding on cans?

Traceability

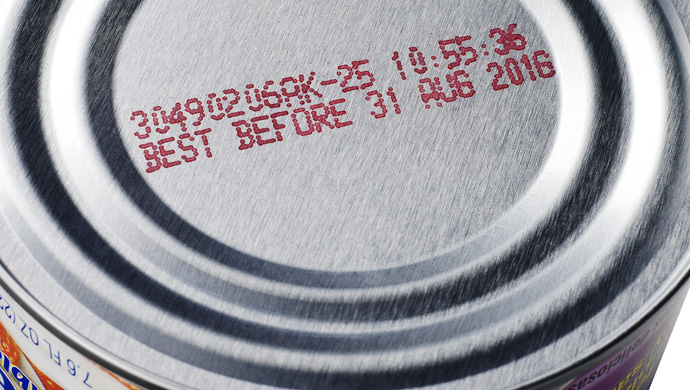

In the event of a recall or quality issue, printing on tins is helpful to identify the source. It contains details like when and where the can was produced, facilitating swift and precise recalls if necessary.

Quality Control

Manufacturers and distributors rely on batch numbers, expiration dates, and other quality-related data to ensure that products meet safety and quality standards.

What are the different ways of Marking and Coding on cans?

Inkjet Marking & Coding Machine

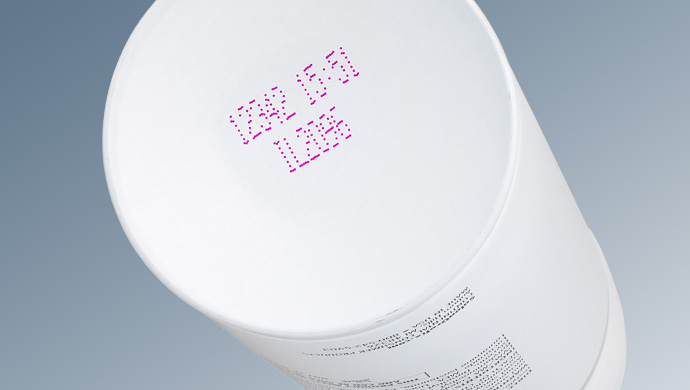

Continuous Inkjet printers are commonly used for marking on aluminium or metal cans. With our Inkjet printer a manufacturer has the flexibility of various fonts and sizes. Videojet printers use quick-drying inks that adhere well to metal surfaces, ensuring durability throughout the product’s lifecycle.

Laser Marking & Coding Machine

Laser technology provides permanent marks on metal cans. It’s ideal for applications where durability and readability are crucial. Laser marking machine are suitable for high-speed production lines.

What type of Codes you can print on Cans?

- Batch Numbers

- Manufacturing & Expiration Dates

- Barcodes

- QR Codes

Suggested Solutions

Additional Resources

Contact Us

Sales and Marketing contact:

9:30 AM – 6:30 PM (Monday – Friday)

Service and Technical support