When it comes to plastic rigid containers, the ability to mark and code these containers accurately and reliably is crucial.

Methods used for marking and coding on plastic containers:

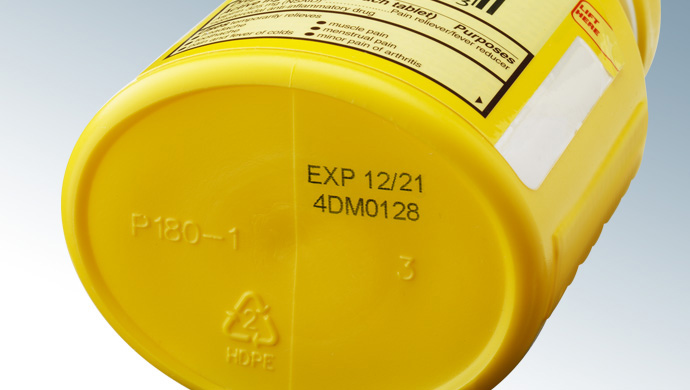

Continuous Inkjet Printer: Non-contact method popular for its versatility and speed. Print alphanumeric codes and barcodes directly onto containers.

Laser Marking Machine: Permanent & high-quality marking often used for serial numbers, and barcodes printing. CO2 laser marking machine and fiber lasers marking machine are commonly used for marking and coding on plastic.

Thermal Transfer Overprinting (TTO): Ideal for high-resolution printing. It uses thermal printhead to transfer ink onto the container. It’s suitable for variable data like expiration dates.

Considerations for Marking and Coding on Plastic:

Substrate Compatibility: Not all marking methods work on every type of plastic. Compatibility testing ensures the chosen method adheres properly without smudging or fading.

Durability: Depending on the product’s lifespan, the code must withstand environmental factors like moisture, UV exposure, and handling.

Speed and Throughput: Production lines require efficient marking to maintain productivity. Inkjet and laser systems are often chosen for their speed.

Regulatory Requirements: Different industries have specific requirements for marking and coding. This includes font size, content, and placement. Videojet’s printing machine adhere to these standards.

Integration with Systems: Automated systems that integrate with existing line to ensure zero downtime.

Suggested Solutions

Additional Resources

Contact Us

Sales and Marketing contact:

9:30 AM – 6:30 PM (Monday – Friday)

Service and Technical support