Also see:

Videojet® 3340 CO2 Laser Marking System

Laser Marking Systems ![]()

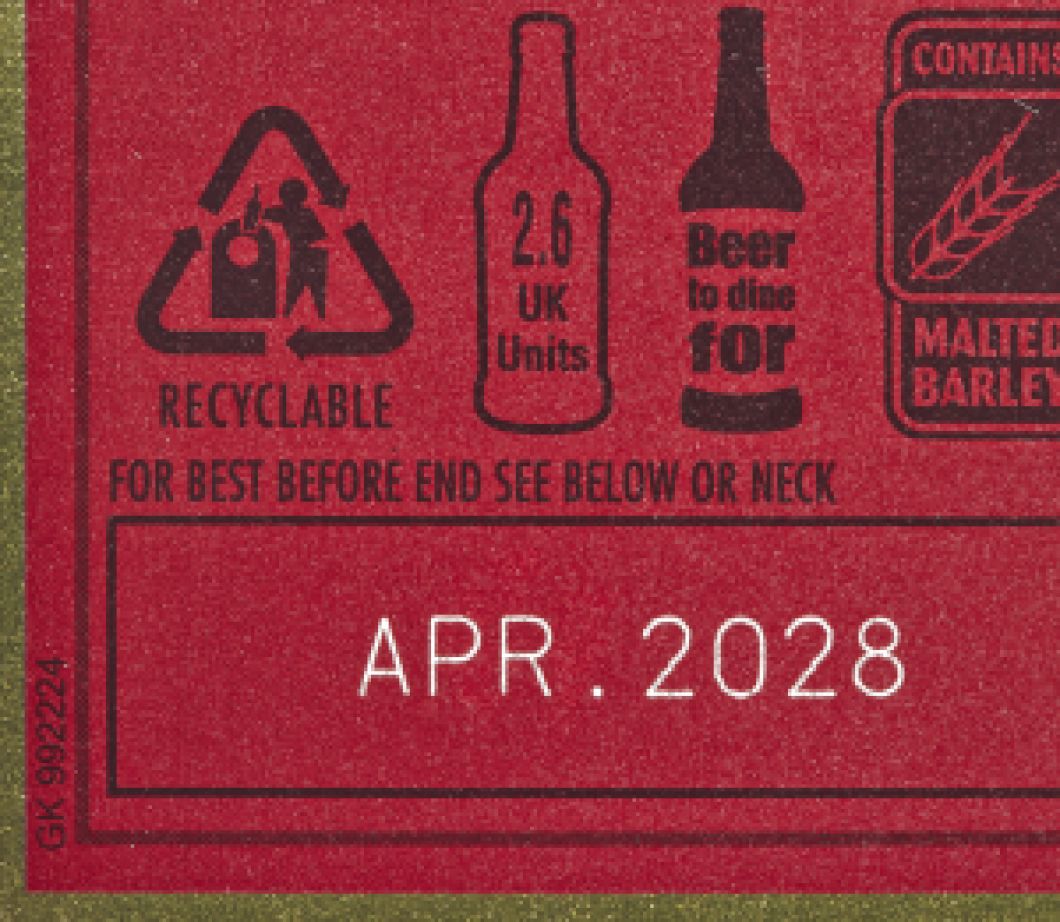

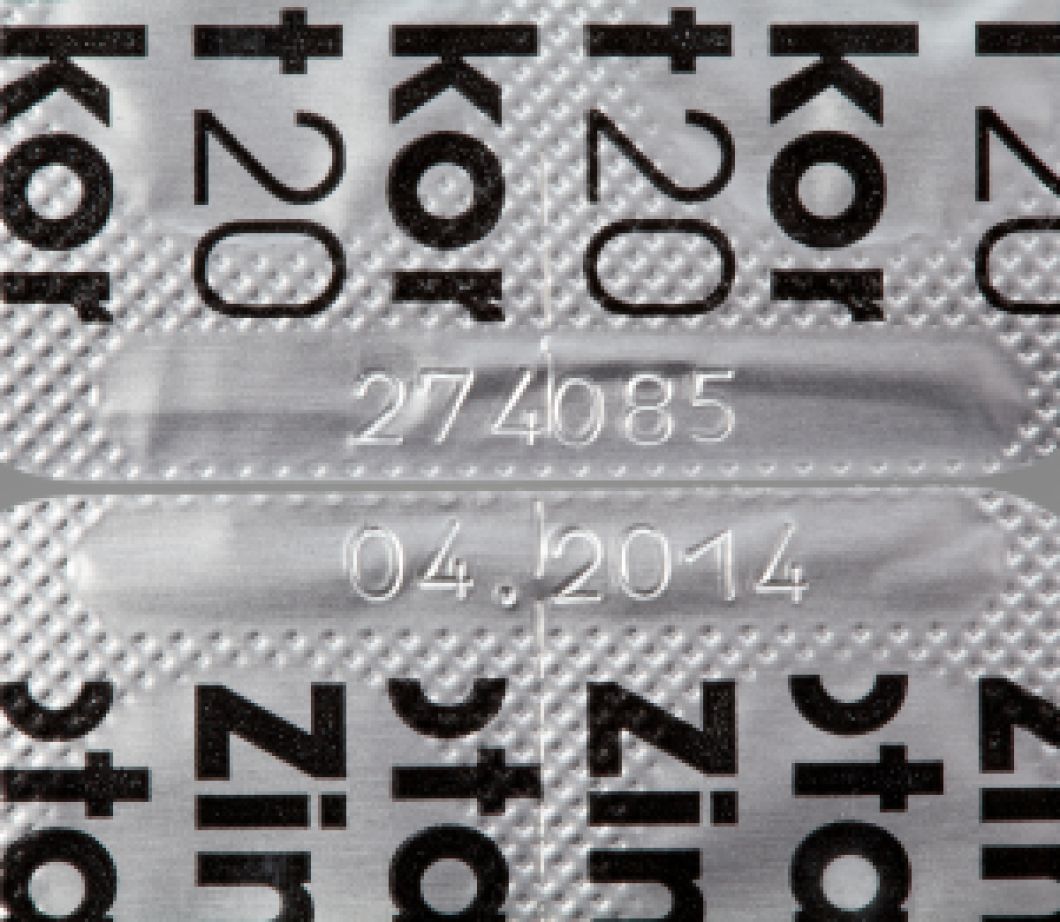

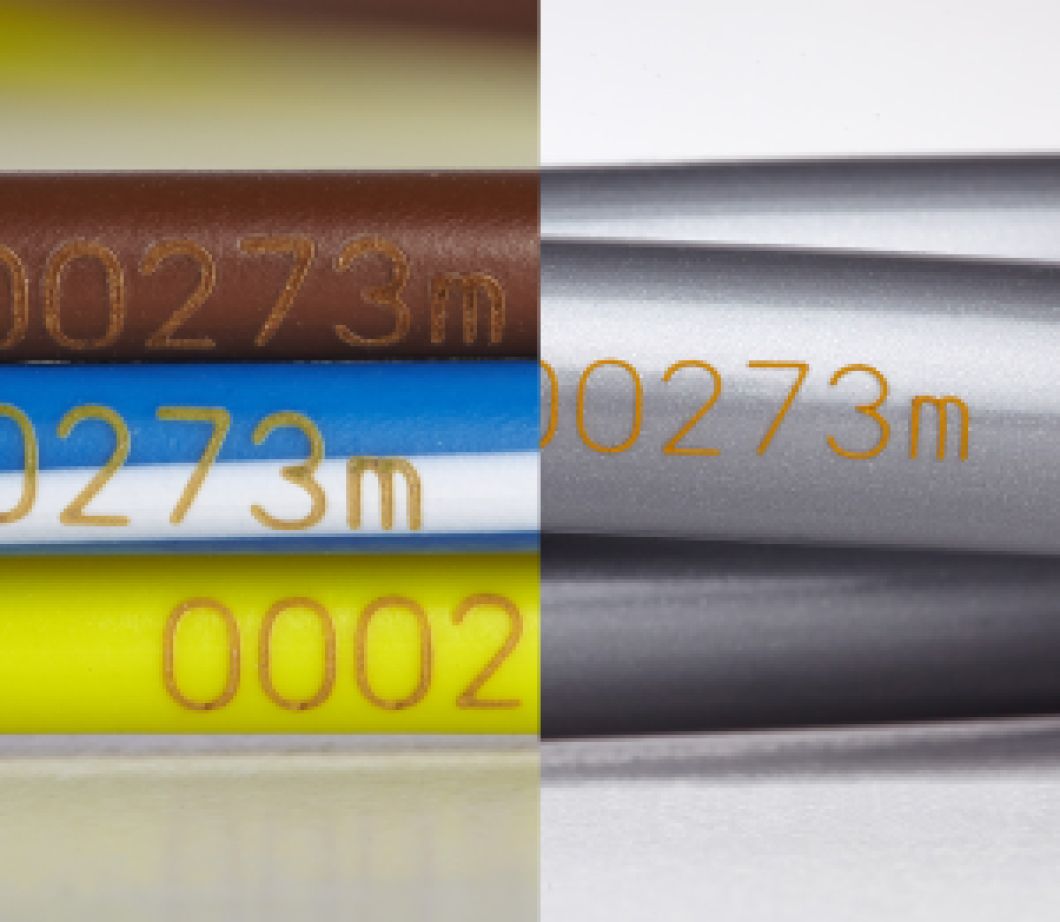

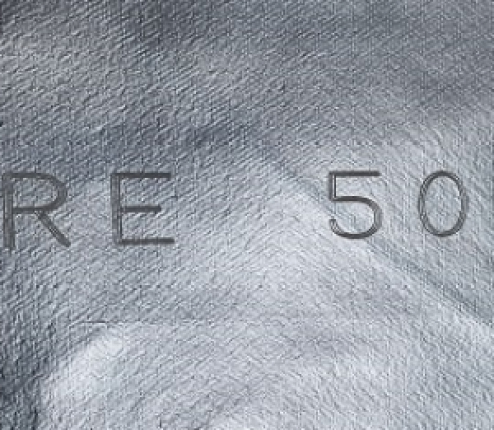

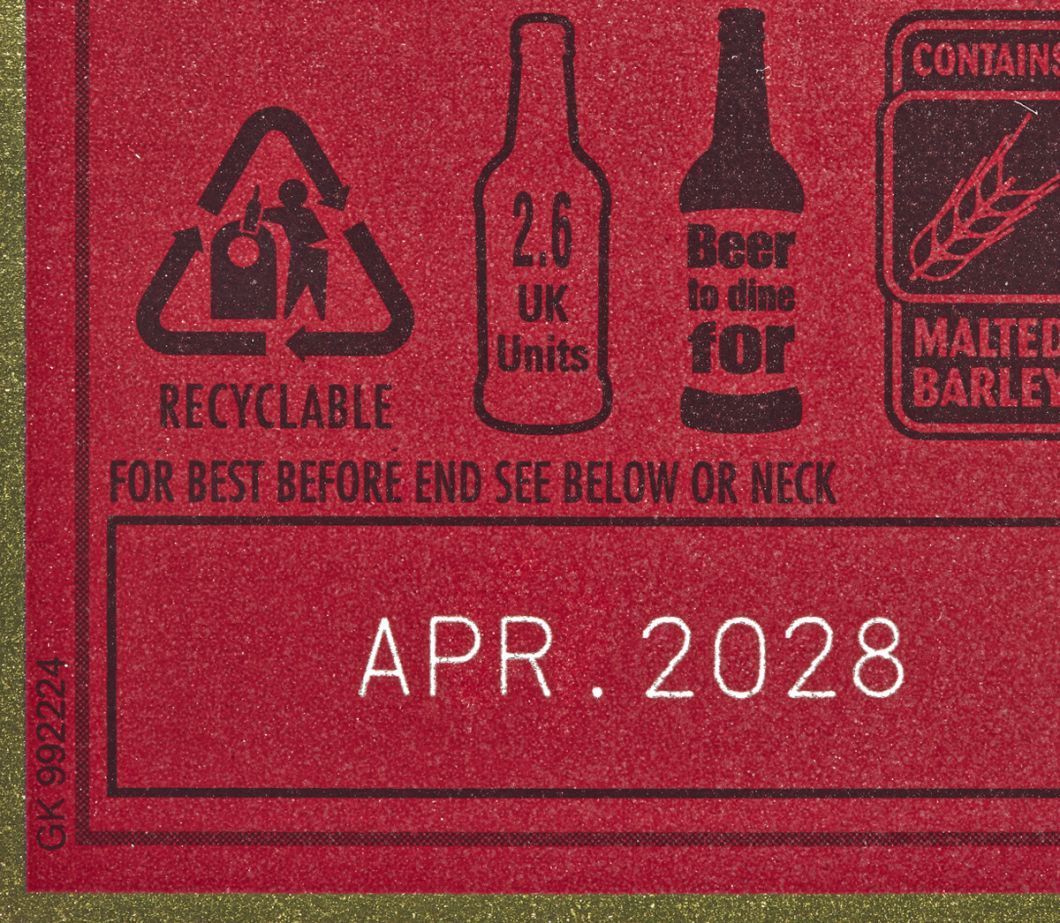

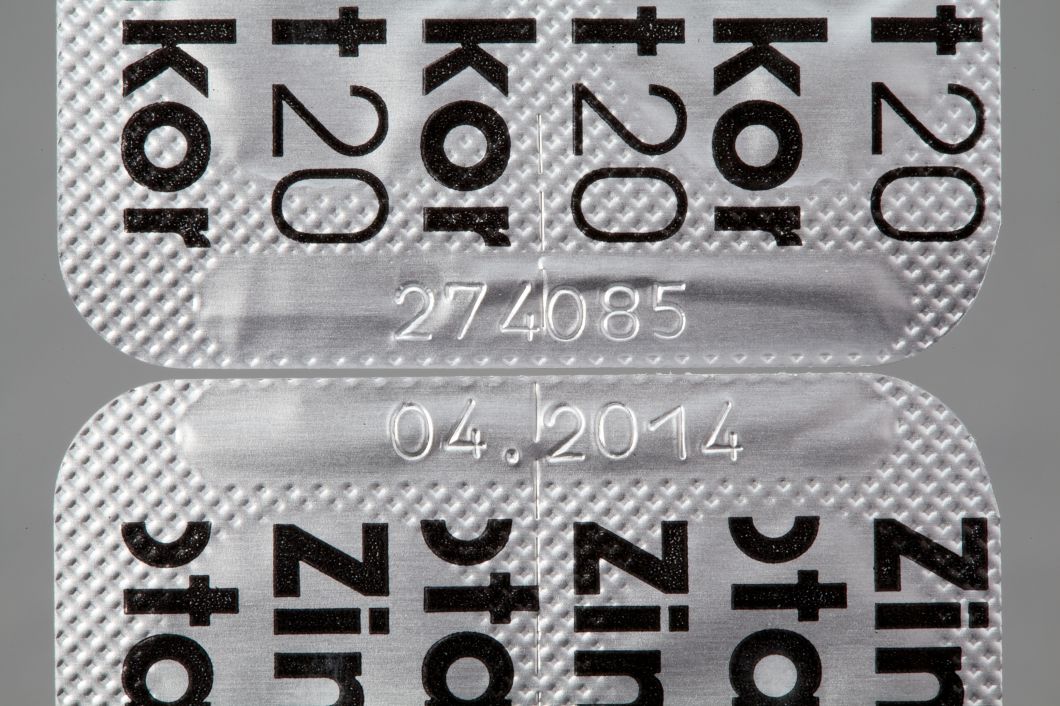

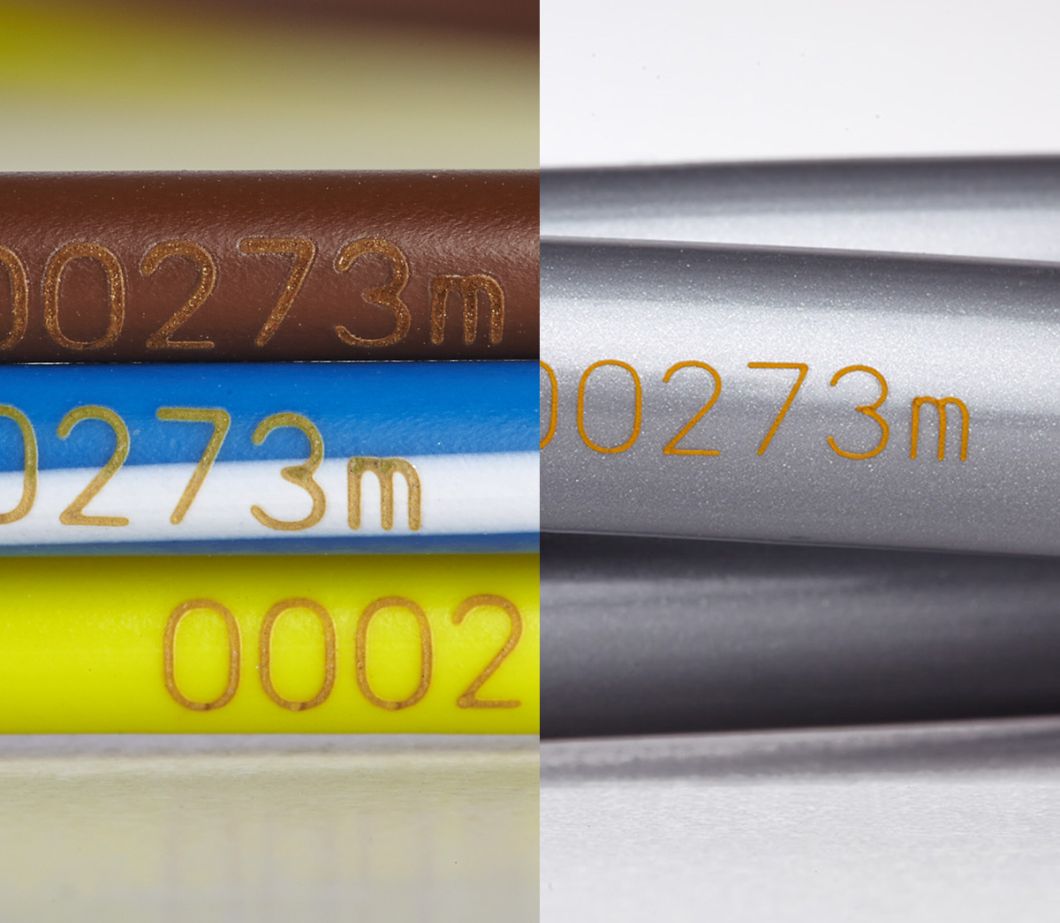

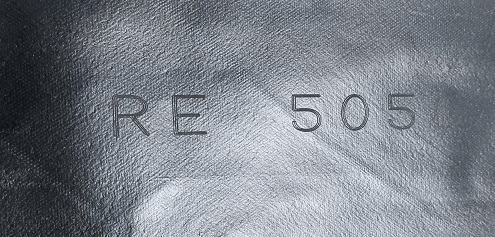

The 3340 30-Watt laser marking system offers a powerful combination of performance and flexibility, delivering high quality marks on moderate to high speed lines. Designed to maintain the best quality codes on high speed lines. Virtually no font, code or graphic restrictions, makes the 3340 an ideal solution for marking complex codes to meet the demand of applications in food, beverage, cosmetics, pharmaceutical and extrusion industries. A diverse combination of marking heads, lenses and wavelength options delivers an industry leading 21 spot size variations to match a broad range of marking effects.

Contact us for New Equipment Sales: +91 72900-62569

Videojet 3340

Specs

| Value | |

| Laser Tube | CO2 |

| Maximum Power | 30W |

| Laser Cooling | Air Cooled |

| Maximum Print Speed | 2000 characters/sec |

| Maximum Line Speed | 900 m/min (2,940 ft/min) |

| Environmental Protection | IP54, 65 |

| Beam Output | Steered Beam |

| Laser Source Expected Life | 45,000 hours |

| Laser Wavelength Options | 10.6 μm, 10.2 μm, 9.3 μm |

| Focal Distance Options | 64 mm (2.50 in) – 600 mm (23.62 in) |

| Maximum Mark Window | 601 x 440 mm (23.66 x 17.32 in) |

| Standard I/O Connectivity | Internal Terminal Connections |

| Standard User Interface | Handheld |

| Optional User Inteface | PC, CLARiTY™ Laser Controller, TCS, Smart Graph Com |

| Umbilical | Detachable , 3 lengths |

| Plant Air Used | No |

| Certifications/Approvals | CE, TÜV/NRTL, FCC Compliance (no certification required): ROHS, CDRH/FDA |

Benefits

Uptime Advantage helps keep productivity up and costs down:

- Laser tube designed with larger gas volume has optimized air-cooling to provide operational life of over 45,000 hours

- Optional IP65 makes printer suitable for harsh environments without need for plant air

- CLARiTY™ Laser Controller reduces operator errors, helping to ensure products are coded correctly and advanced productivity tools identify the root cause of downtime events to make sustainable process improvements.

Engineered for high performance and quality:

- Highly focused laser beams achieve better performance (mark contrast) than other laser solutions without needing higher power

- Three available laser wavelengths, four marking heads and thirteen lenses for optimal code quality on your specific materials

- High speed communication and buffering of variable data content delivers improved character formation, over other laser solutions, for customers who don’t need top speed, allowing more time to engage the product, resulting in crisp, legible codes

Flexibility and simple usability comes as standard:

- Largest marking field in the industry (up to 600mm width) offers optimally matched applications for faster marking, increasing discrete product throughput or marking multiple messages across a wide web application using only one laser

- 32 standard beam delivery options for integrating the laser marking system into your packaging or filling equipment can help produce the best system uptime

- Focus finder tool for quick set up of accurate focal distance and detachable umbilical for easy integration and line changeover

“Improved line flexibility allowed for rapid implementation of changes to carton labeling. Eliminating labels achieved significant cost savings.”

Mike Wilcox – Senior Project Manager, Ascensia Diabetes (case study)

“The Videojet lasers have not had a single glitch since they were installed and are working well every day!”

Mr. Jose Luis Munoz – Manager, Avicola Velasco (case study)

“From an operator’s point of view, the Videojet lasers are far easier to work with.”

Barry Murray – Operator, Diageo (case study)

Applications

Resources

Documents

Related Products

Videojet 3140 CO2 Laser | Videojet 3340 CO2 Laser | Videojet 3640 CO2 Laser | |

| Max Line Speed (m/min) | 900 | 900 | 900 |

| Max Print Area H x L (mm) | 485 x 351 | 601 x 440 | 601 x 440 |

| Code Type | |||

| Line Location | Product Marking, Case Marking | Product Marking, Case Marking | Product Marking, Case Marking |

| Applications | Corrugate – Direct Marking Corrugate – Labeling Direct Food Contact Flexible Film, Foils, Labels Glass Metal Plastic – General Plastic – PET Rubber Wood and Lumber | Corrugate – Direct Marking Corrugate – Labeling Direct Food Contact Flexible Film, Foils, Labels Glass Metal Plastic – General Plastic – PET Rubber Wood and Lumber | Corrugate – Direct Marking Corrugate – Labeling Direct Food Contact Flexible Film, Foils, Labels Glass Metal Plastic – General Plastic – PET Rubber Wood and Lumber |

Contact us

Let Us Find the Right Solution for Your Business

A Coding Expert will contact you within 1 business day

Need help? We’re here for you.

New Equipment Sales & Quotes:![]() +91 72900-62569

+91 72900-62569

Service & Tech Support:![]() 1800-103-4812

1800-103-4812

E-mail:![]() marketing.india@videojet.com

marketing.india@videojet.com

Quick Links:

Global Offices

Sales and Distributor Search