In packaging industry marking and coding on flexible films and foils stand as crucial elements. Often used for packaging in industries from food and beverage to pharmaceuticals.

Importance of Marking and Coding:

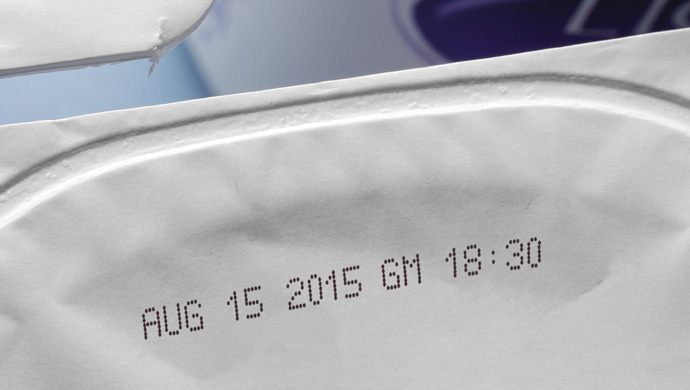

Marking and coding is important in the packaging industry, serving both functional and regulatory purposes. Firstly, they provide information such like expiration dates, batch numbers, and barcodes. Moreover, they enable brand identification, ensuring consumer trust and brand integrity.

Different methods for Marking and Coding:

Continuous Inkjet Printer: CIJ printers are widely used for their versatility and high-resolution capabilities. It offers fast drying times making it ideal for variable data printing on any substrate.

Laser Marking Machine: Laser marking provides permanent, high-contrast marking without physical contact, making it suitable for delicate and heat-sensitive materials like foils. It offers durability and precision.

Thermal Transfer Printing: TTO printers use heat to transfer ink from a ribbon onto the substrate. Thermal transfer printers are commonly used for barcoding and labeling applications, providing high-quality, long-lasting marks.

Suggested Solutions

Additional Resources

Contact Us

Sales and Marketing contact:

9:30 AM – 6:30 PM (Monday – Friday)

Service and Technical support