From automotive to electronics, and from pharmaceuticals to consumer goods, glass bottle and containers serves as a versatile material because of which marking and coding on glass surfaces are crucial for product identification, traceability, and aesthetic appeal.

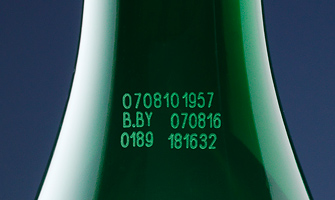

Laser Marking on Glass Bottle:

Marking and coding on glass bottle and container with laser marking machine is a popular method for its precision and versatility. It Uses laser beam to create high-resolution marks without damaging the glass surface.

Benefits of using Laser marking machine:

- High precision and resolution.

- Minimizing the risk of surface damage.

- Compatibility with various glass types.

- Resistant to chemicals, and environmental factors.

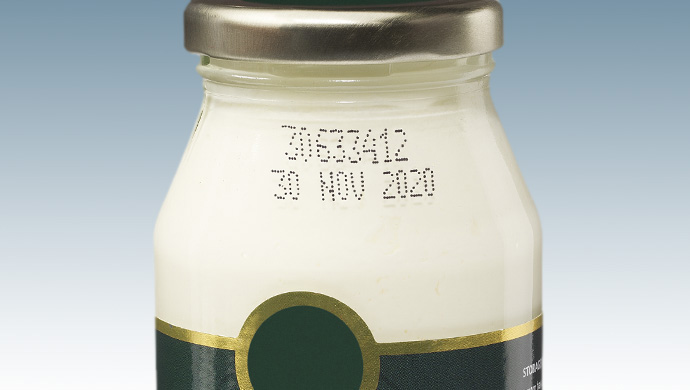

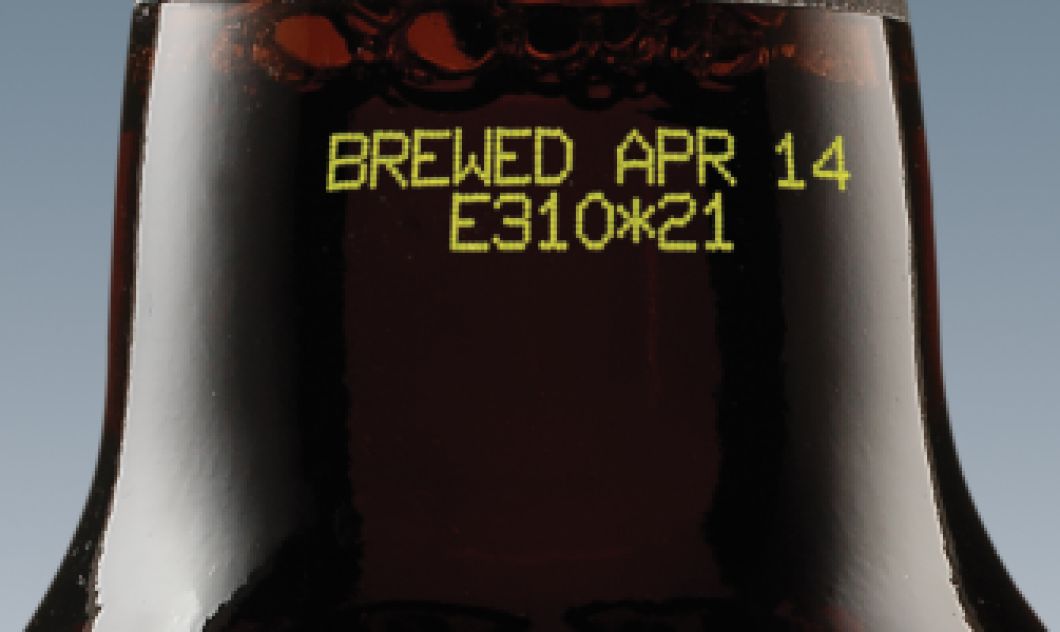

Continuous Inkjet Printer for Glass Container:

Another widely used method for coding on glass which involves ejecting droplets of ink onto the glass surface to create text, number, or logos.

Advantage of using CIJ printer:

- High-speed printing capabilities.

- Compatibility with various inks for adhesion to glass substrates.

- Low maintenance and minimal setup time.

Suggested Solutions

Additional Resources

Contact Us

Sales and Marketing contact:

9:30 AM – 6:30 PM (Monday – Friday)

Service and Technical support