View More About Videojet Thermal Transfer Overprinters (TTO) for Printing on Flexible Packaging and Labels

Videojet Thermal Transfer Overprinters (TTO) : Quick, simple and virtually error-proof operation

Thermal transfer printing, also known as thermal transfer overprinting (TTO), is a digital technology used to print high-resolution, variable-content codes onto thin, flexible packaging such as films, pouches, and labels.

Typical thermal transfer overprinting applications include snack foods, confectionery and bakery products, frozen and refrigerated foods (meat and poultry, dairy, bagged fruits and vegetables), cosmetics, pharmaceuticals, nutraceuticals, and other products packaged in flexible films.

Discover more about our thermal transfer overprinters (TTO)

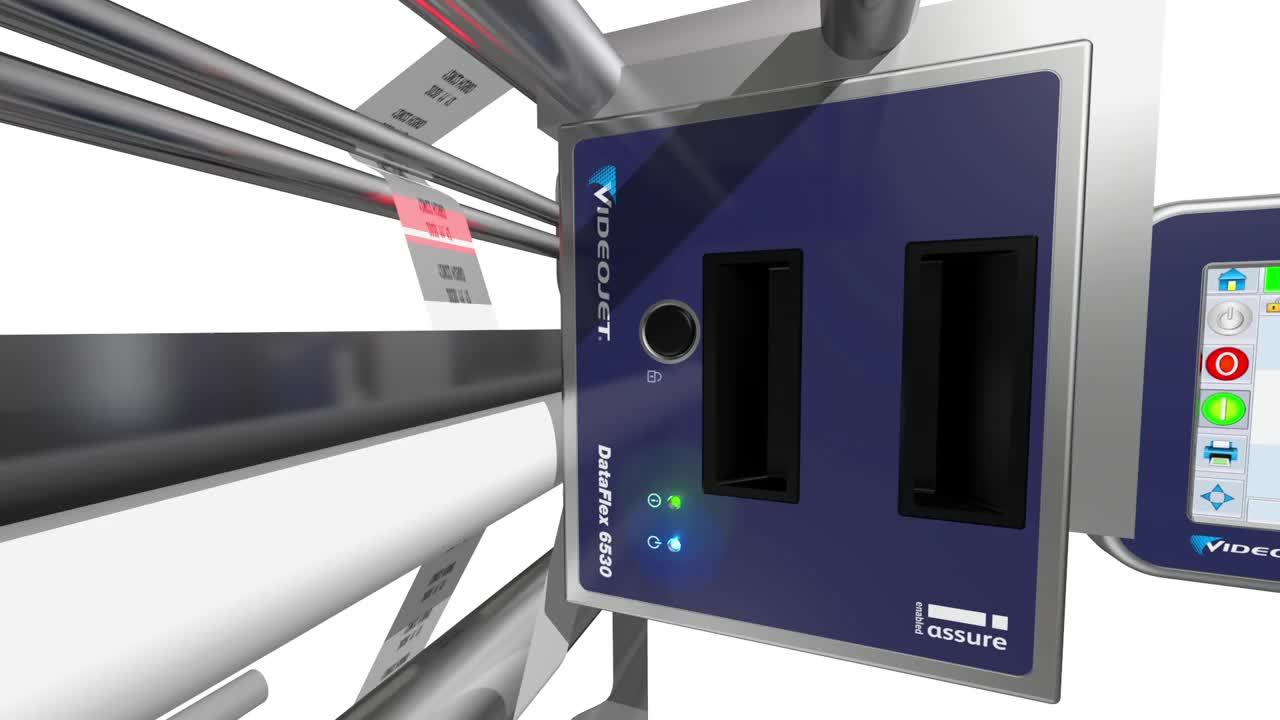

Videojet DataFlex® 6530 & 6330 TTO printers

The 6530 and 6330 are part of the Videojet DataFlex® range of thermal transfer overprinters (TTO), which are designed to give you a more productive operation. These printers embody the latest technology to further improve uptime while reducing time spent on quality checks, waste, and rework to help drive productivity, quality, and efficiency.

Videojet DataFlex® TTO solutions are designed to withstand tough production line environments. With minimal wear parts, an airless, all-electronic design, and quick change ribbon cassette, the enhanced DataFlex 6530 and 6330 TTO printers offer maximized uptime advantage and integration flexibility.

Learn more about the Videojet DataFlex® 6530 & 6330 here.

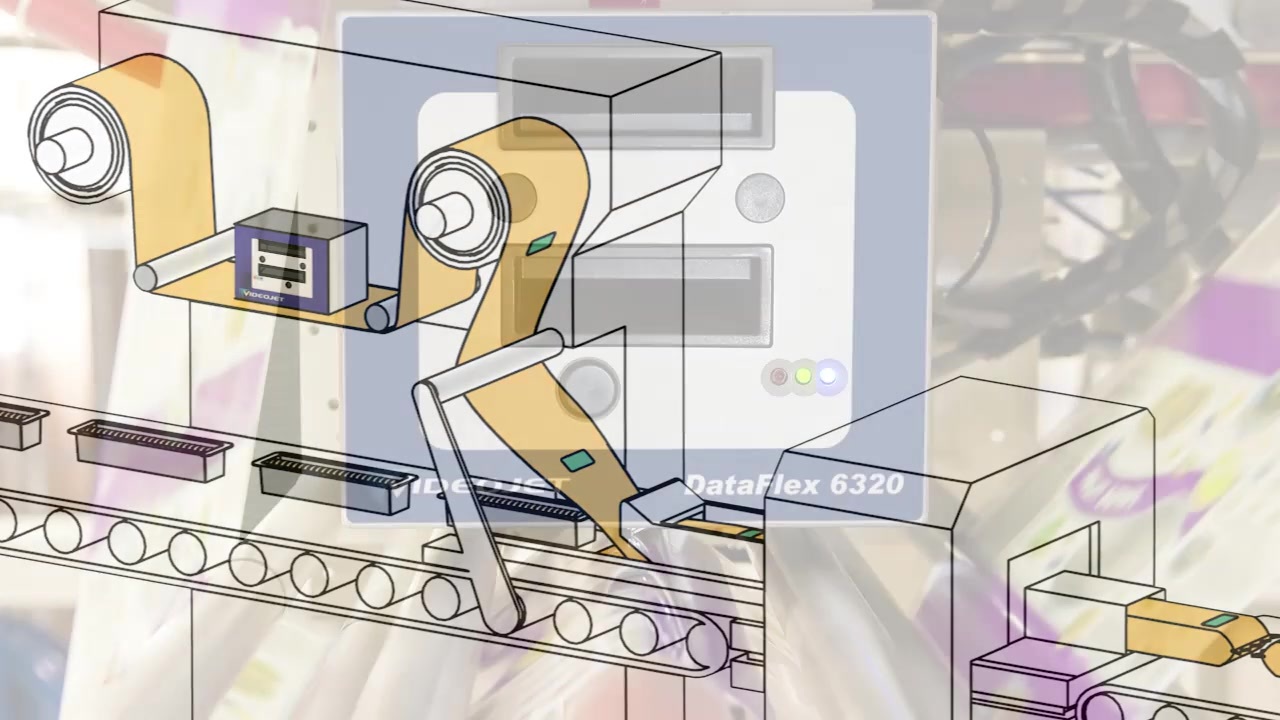

Videojet DataFlex® 6230 TTO printer

The Videojet 6230 is part of the Videojet TTO family which are designed to help increase your productivity. The Videojet 6230 utilizes the latest technology to help reduce flexible packaging coding errors, and improve Total Cost of Ownership (TCO) through a proven and cost-effective solution.

The 6230 TTO delivers easy usability with an intuitive tablet-like 5’’ touchscreen controller with CLARiTY™ interface. The simple ribbon path helps to ensure fast changeovers and a more efficient operation.

Learn more about the Videojet DataFlex® 6230 here.

Learn more about thermal transfer printing technology

Thermal Transfer Overprinting vs. Hot Stamp Printing

To learn more and find out why to choose a TTO printer, click here.

It’s an ongoing challenge for manufacturers and co-packers to meet today’s package coding requirements while reining in operating costs.

One simple way to achieve greater printing capabilities on flexible packaging while actually reducing costs is to upgrade from analog hot stamp printing to digital thermal transfer overprinting (TTO) technology.

Both hot stamp printers and thermal transfer overprinters are designed to transfer ink from an inked ribbon onto a thin, flexible substrate such as synthetic films or labels. However, operationally, the two printers are very different.

Thermal transfer printing technology, an ideal solution for flexible packaging!

Intermittent Thermal Transfer Printing

Intermittent thermal transfer printing is used on lines where the packaging film moves in an intermittent motion (stop/start). The stop-time (dwell) within the cycle is used for printing. Using a signal from the packaging machine, the printer lowers the printhead onto the material and moves across the film to print. When complete, the printhead is raised and moves to the start position for the next package.

Continuous Thermal Transfer Printing

On continuous flow lines, the packaging material is printed while the film is moving. The film runs between the printhead and a platen roller. After a start signal from the packaging machine, the printhead is pressed against the platen roller and printing is started. As the film is pulled through the filler, the printer prints on every package. A stop print signal causes the printhead to be raised.

Read more about how TTO printing technology is the ideal solution for flexible packaging and a guide to selecting TTO ribbons here.

To know more or get expert advice regarding printing on flexible packaging such as films, pouches, and labels, contact us.

Videojet iAssure™ technology, a built-in code quality checker in our 6530 and 6330 TTO printers

Watch how the revolutionary Videojet iAssure™ integrated code quality assurance technology continually checks for print defects by taking a picture of every single code with built-in sensors, assesses the quality, and if chosen limits are exceeded, rejects the code or stops the line to reduce waste and rework.

Vidoejet iAssure™ technology is exclusively built into the Videojet DataFlex® 6530 53mm and the 6330 Thermal Transfer Overprinters.

Learn more about Videojet iAssure™ technology here.

Check out some advantages of choosing the Videojet TTO line of printers

Fill in your details below to receive latest updates from Videojet

Know more about Industry Case studies about Videojet!

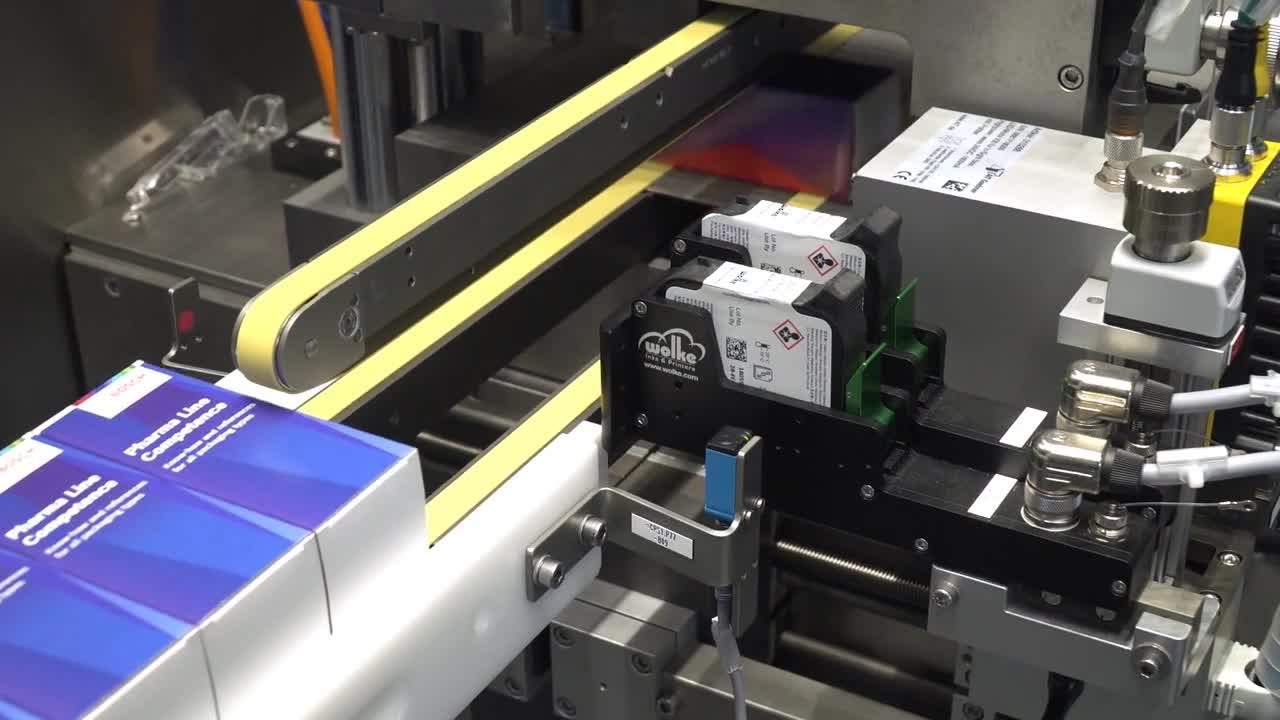

Case Study: Bosch Packaging Technology

Find out how Bosch utilizes the Wolke m610 OEM for a powerful track and trace solution.

Click below to View!