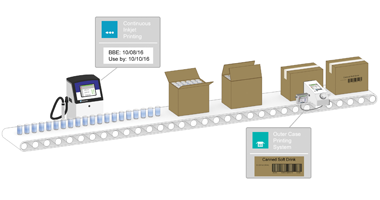

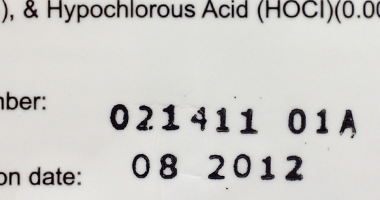

“Best before” dates indicate to purchasers whether food and beverage products or other consumables are safe to buy based on when they were produced and packaged. Many versions of these warnings to consumers are required by regulators and are closely scrutinized by shoppers.

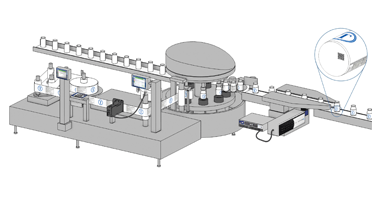

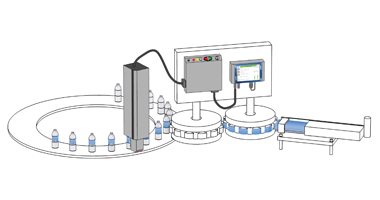

The conditions under which products are packaged can make the clear printing of these messages difficult. This is especially true of beverages and frozen foods, which are processed in environments that can leave moisture on the package surface. Best before date stamp machines must be able to imprint permanent marks regardless of these conditions. In addition, the lines filling these products are quite often operating at high speeds, and any coding equipment must be able to print clear codes at those high speeds.

These challenges make the printing of best before dates accomplished most effectively by inkjet printers. These systems can not only print permanent, readable codes at high speeds, they can be programmed to quickly change the date and time information being printed to maintain accuracy.

The productivity of these production lines is critical to the manufacturer. If a critical element of the line, such as the best before date coder, stops printing, it stops the line, directly affecting productivity. These systems, therefore, must be manufactured to be extremely reliable and the consumables they use, including both ink and solvent, be replaced efficiently when they run low.

Today’s efficient date coders often include features that monitor consumables closely to ensure that users are aware when they will need to be replaced. Alerts regarding levels may be sent to the printer’s HMI screen, or sent via text message directly to the line operators or supervisor. This ensures that downtime to replace consumables is kept to a minimum, supporting high line productivity.

Categories

- Automatic Batch Coding Machine

- Automatic MRP Printing Machine

- Bagging Machines

- Bottle Filling Machines

- Carton Labeler

- Extruder Machines

- Flexible Product Packaging

- Food Packaging

- Forming Machines

- Product Marking

- Product Coding

- Production Lines

- Product Labeling

- Tetra Pack Printing

- Tracking & Traceability

- Vacuum Sealers

- Variable Data

Contact Us

Sales and Marketing contact:

9:30 AM – 6:30 PM (Monday – Friday)

Service and Technical support