Integrated Marking and Coding Solutions for Product Tracking and Product Traceability

The tracking of a product or package enables the viewer to identify the location of the object at the current time. Traceability reveals the path a product has taken from production through distribution to its destination. Both of these tasks require the printing of an identification code on the product or package, which can then be accessed at any time through an online tracking system. For tracking, this may be a basic bar code; for traceability more sophisticated, and often unique, codes are often required.

These codes enable the detection of products that have been diverted from the normal distribution chain, costing companies revenue. They also enable companies to efficiently identify and target products that need to be recalled because they may present a threat to consumers. A quick response during helps build trust with customers.

In some industries, such as food production, batch number, expiry date, date of manufacture, serial number and product description codes are common examples of the codes used for traceability. In other industries, including pharmaceuticals and medical devices and their individual parts, unique product identification codes are used as a means to identify, track and trace genuine products through distribution. The unique identification codes used also ensure that the coded products are genuine, since makers of counterfeit products will not have access to the secure international databases from which the unique codes are drawn.

Individual packaged products area coded, then, in a process called aggregation, packaged products in sleeves, cartons, cases and pallet loads are also coded. Reading the code of a pallet load, for example, will access all the codes of the individual packaged products in the load.

Originally used almost exclusively in pharmaceutical production, unique traceability are beginning to be used also in food production, providing traceability of foods from processing through retail stores. The ingredients found in finished food products are also often coded, so that they can traced back to their original source in the event of a recall due to contamination.

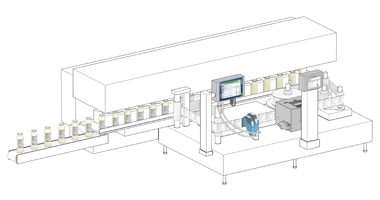

The tracking and traceability codes are applied by marking systems able to efficiently and cost-effectively apply the codes at production line speeds while ensuring that they are clear and readable. These can either inkjet or laser marking systems, depending on the materials to be marked and the conditions the coded objects may encounter that can affect the codes. The quality of applied codes is usually confirmed by a vision system either as part of the marking process or immediately after.

Categories

- Automatic Batch Coding Machine

- Automatic MRP Printing Machine

- Bagging Machines

- Bottle Filling Machines

- Carton Labeler

- Extruder Machines

- Flexible Product Packaging

- Food Packaging

- Forming Machines

- Product Marking

- Product Coding

- Production Lines

- Product Labeling

- Tetra Pack Printing

- Tracking & Traceability

- Vacuum Sealers

- Variable Data

Contact Us

Sales and Marketing contact:

9:30 AM – 6:30 PM (Monday – Friday)

Service and Technical support